14+ Preventive Maintenance Schedule Examples

In business, equipment such as machines, pumps, and electrical wirings have always been the assets of every company. These materials help in providing efficiency and convenience that would be beneficial for every client. But so long since you have probably been using your resources for your company. But remember that they, too, are prone to damages that could pose potential risks to every employee. With that, it would be mandatory to keep everything in good condition. Therefore, you have to prepare a preventive maintenance schedule to secure regular property management. This helps you set appointments for a day for particular equipment, which also enables you to track your progress from time to time.

14+ Preventive Maintenance Schedule Examples

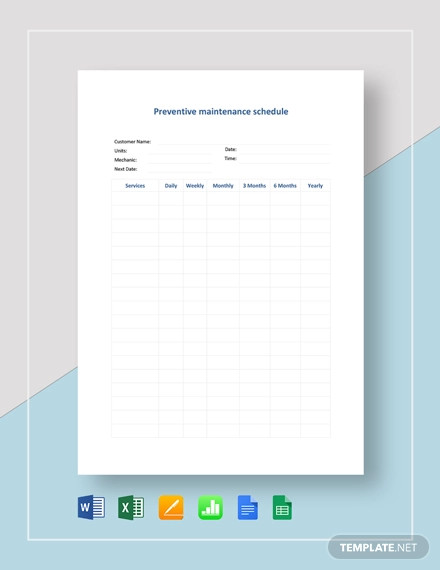

1. Preventive Maintenance Schedule Template

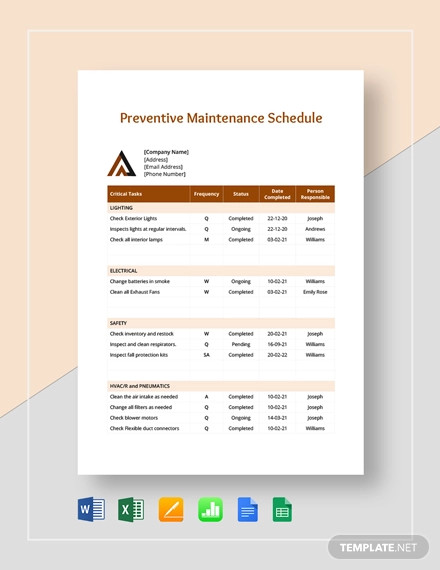

2. Sample Preventive Maintenance Schedule Template

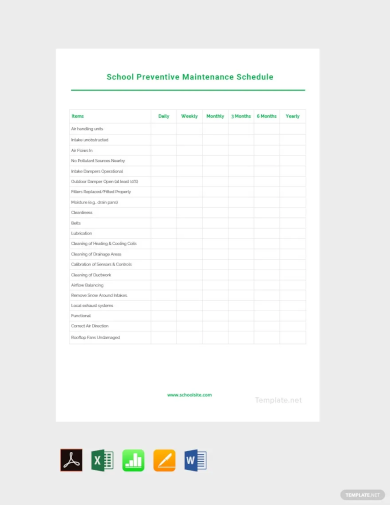

3. Sample Preventive Maintenance Schedule Template

4. Preventive Maintenance Schedule Template

5. Planned Preventive Maintenance Schedule Template

6. Preventive Maintenance Schedule

7. Weekly Maintenance Schedule Template

8. Vehicle Maintenance Schedule Template

9. Equipment Maintenance Schedule Template

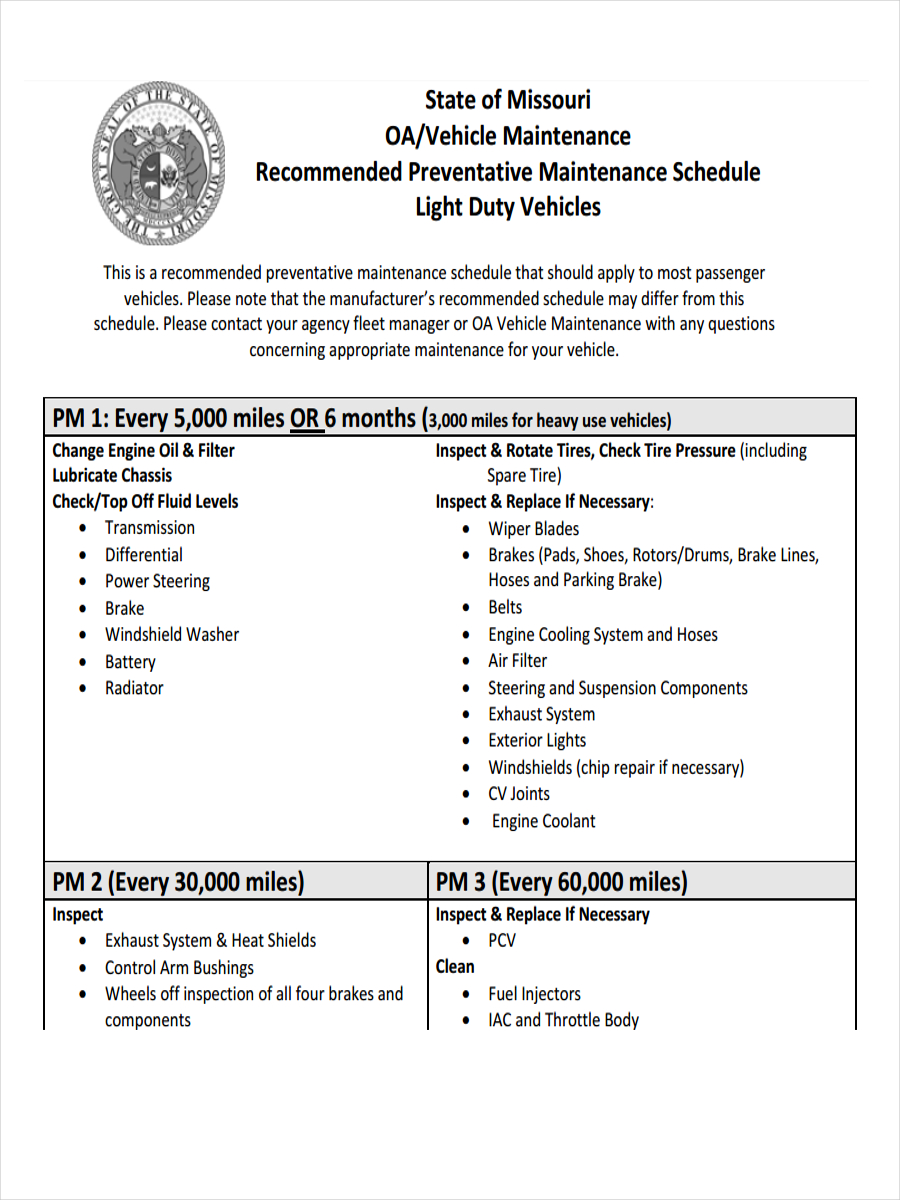

10. Vehicle Preventive Maintenance Schedule

11. Schedule for Equipment Preventive Maintenance

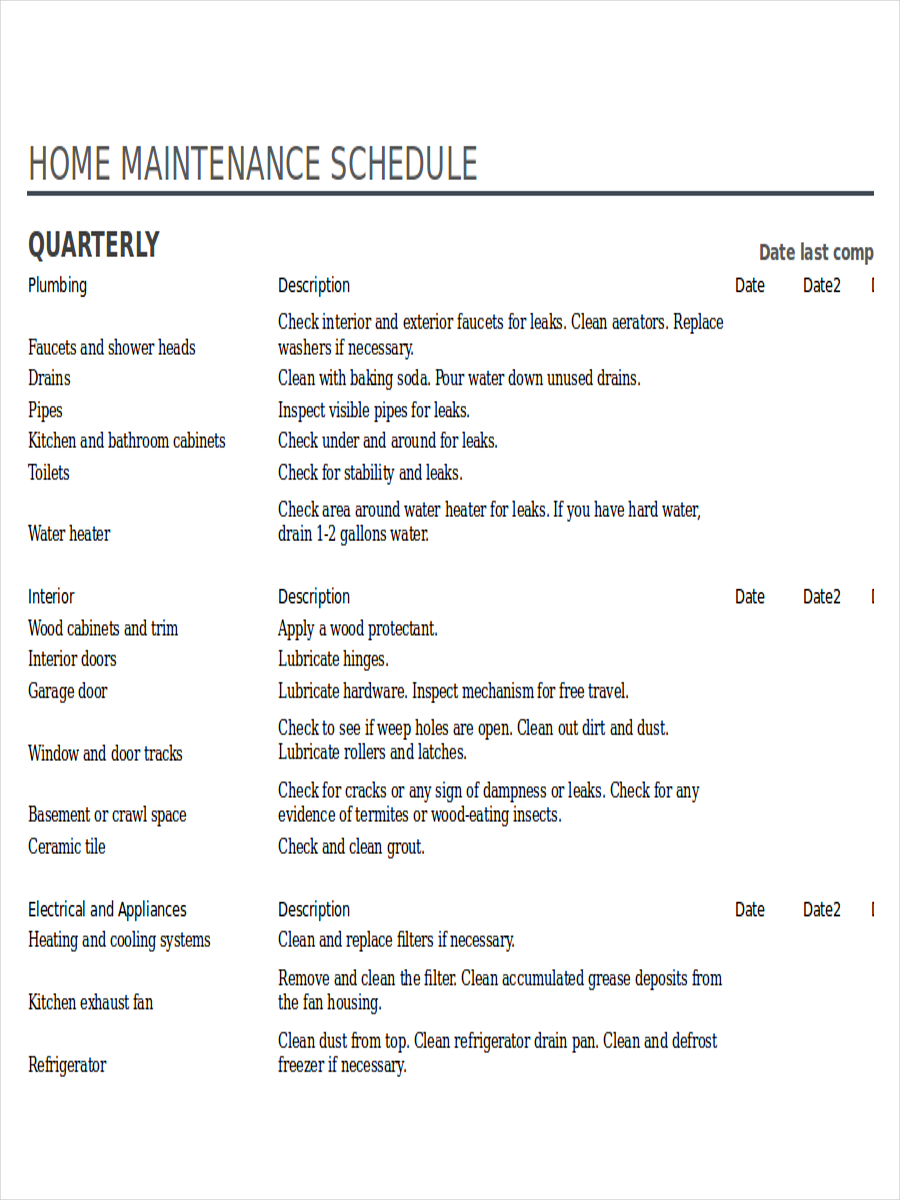

12. Home Preventive Maintenance Schedule

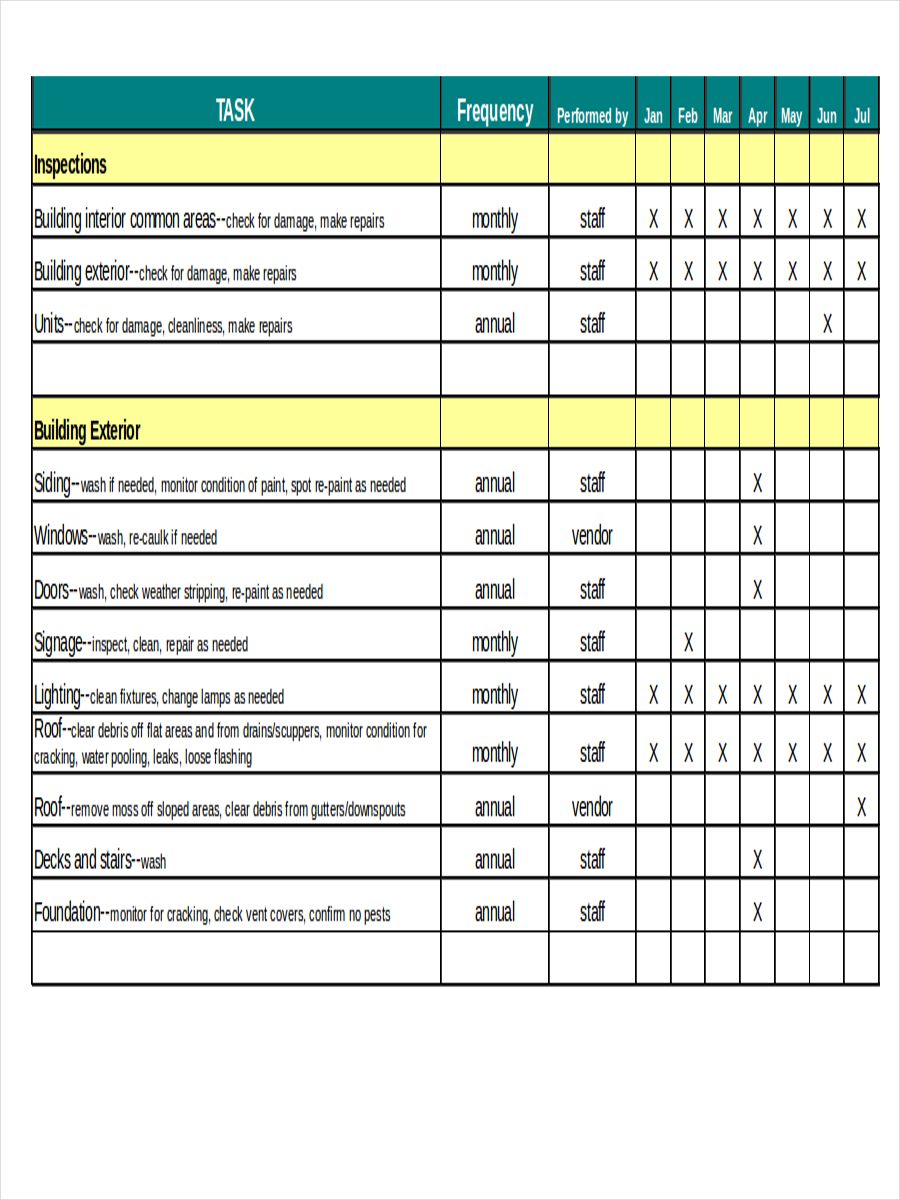

13. Building Preventive Maintenance Schedule

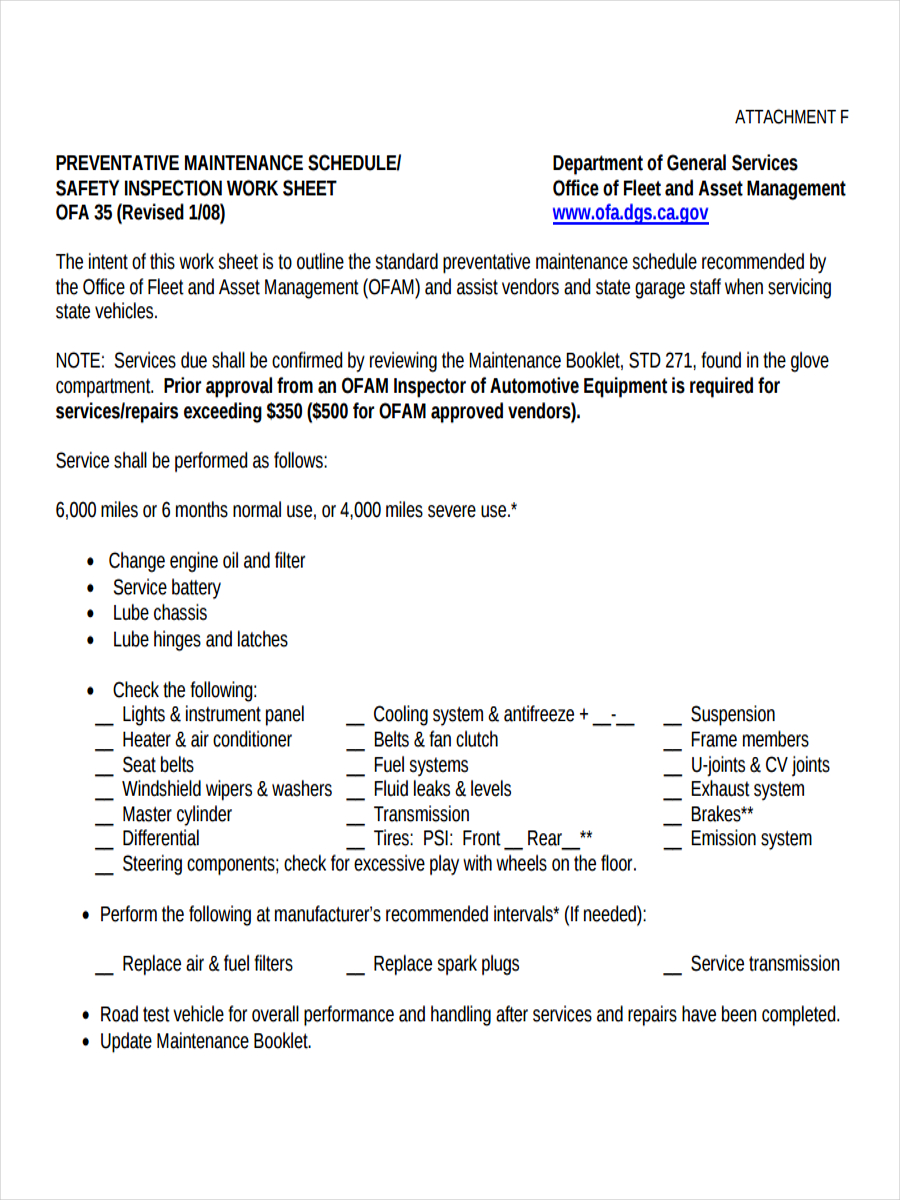

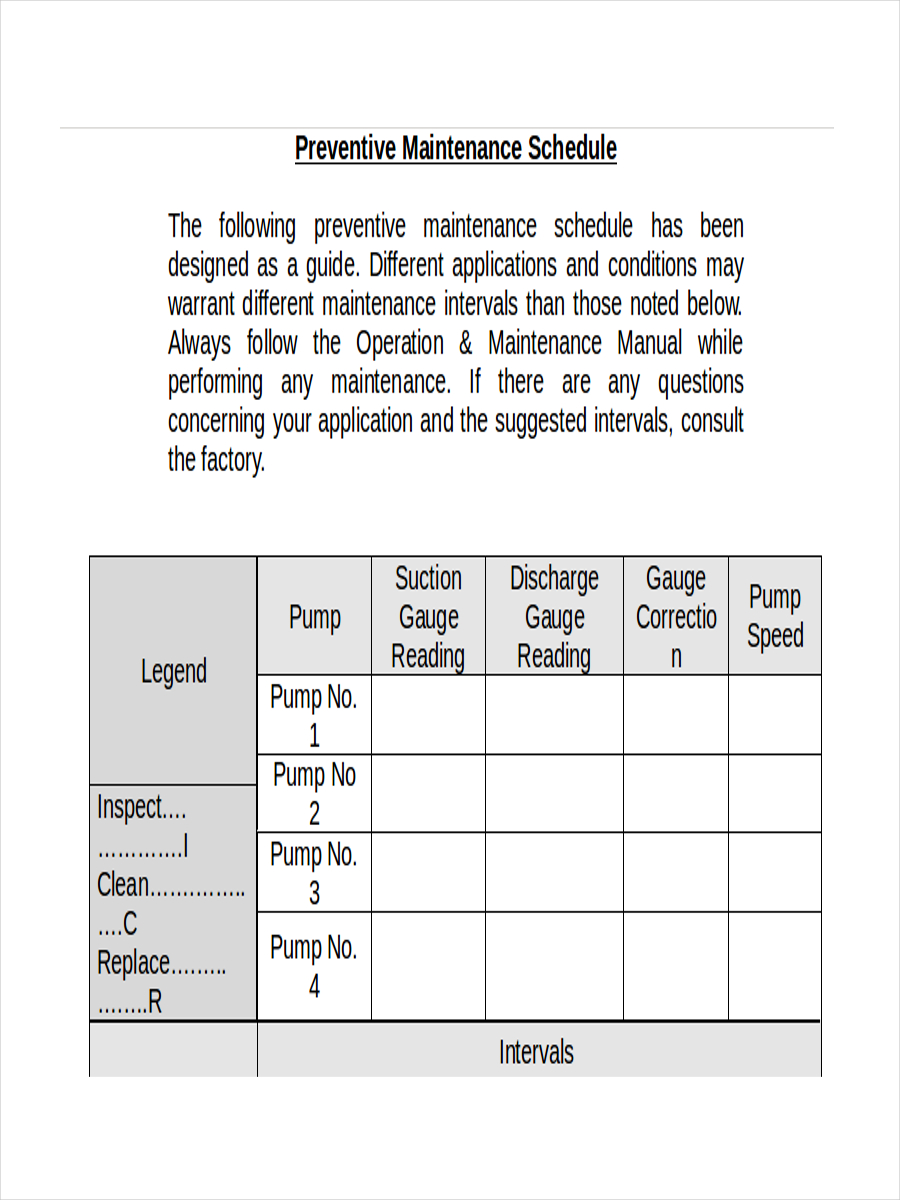

14. Sample Preventive Maintenance Schedule

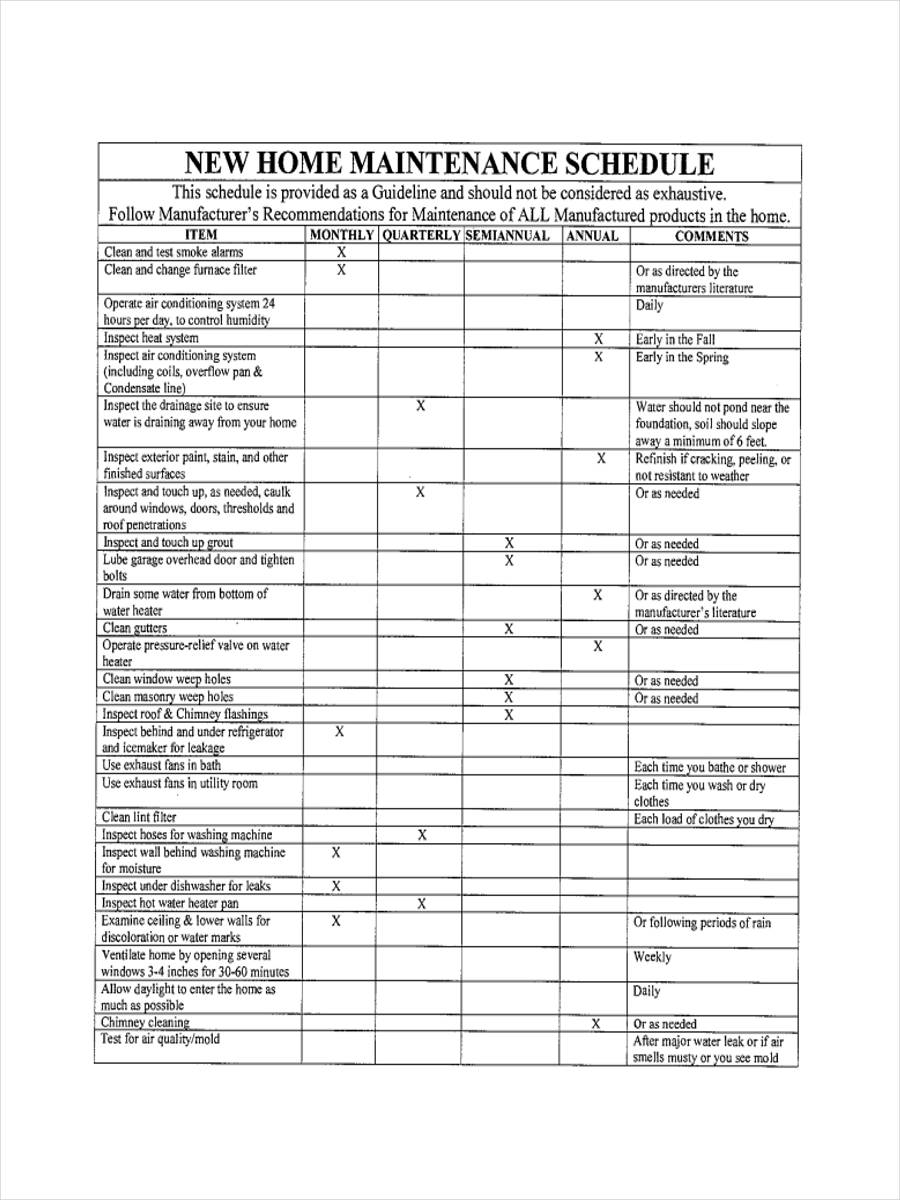

15. New Home Preventive Maintenance Schedule

What Is a Preventive Maintenance Schedule?

A preventive maintenance schedule is a document that contains a list of service checks of equipment. It is a periodical checking of a company’s resources to ensure that the operation would avoid fallbacks. This, too, helps in preventing unnecessary delays and accidents in the workplace.

The Worth of Wrongful Injuries at Work

No matter how much you provide an effort to give convenience to your employees in the workplace, there will always be unexpected damages that could severely affect the situation. Part of that is the equipment that is typically used every day without weekly or monthly maintenance and checking. Perhaps, according to a report published by the Injury Facts, the finances of work injuries reached $170.8 billion in 2018. It’s a significant number, which also explains that maintenance in resources is an absolute necessity. Therefore, primary to solving these issues must be addressed within the employee training plan and maintenance schedule.

How To Make a Preventive Maintenance Schedule

There are a hundred different ways of conducting an equipment maintenance schedule to a wide variety of machines and applications. One must be keen on details to make sure everything will go according to the maintenance plan. As there are formats and elements that you must consider, perhaps, it would be an easy process if you consider the steps below.

1. Prepare an Equipment Inventory

When preparing a maintenance visual board for your team, it would be beneficial to always start by creating an equipment inventory. Take your time to evaluate what are the materials and resources involved in your daily operation. You can make a checklist based on what type of company you run. You may include grinding machines, cold cut saws, and even shears. The more accurate list, the better. With this, you can easily incorporate the procedures you will do in the later steps.

2. List Down all Maintenance Procedures

Once you finally record all the equipment involve, the next thing you should do is to organize the tasks required to maintain or fix each item. Note that correctness is mandatory in any work schedule. Therefore, you have to add the list of maintenance jobs that your employees will follow. For example, in HVAC preventive maintenance, inspecting and changing filters are typically the first steps, followed by cleaning the entire system. Having a proper step by step guide will help employees avoid further damages.

3. Make a Timetable

But aside from the list of tasks, what is important is to finish them on time. Here, if machines or equipment are mandatory to undergo monthly preventive maintenance, you have to pull off that monthly schedule. Some may need to have weekly or even yearly assessments. In each task, label them with the accurate date and time. But remember to put intervals for thorough forecasting that requires greater skills. So, since one maintenance task may take two to three days to finish, you have to finish them on that exact time duration, or else, extensions may cause a delay. More so, it could affect your monthly productivity and performance.

4. Make an Analysis and Adjustments

Lastly, once you have finished the timetable, it would be best to have it checked by the authorized personnel. In this way, they can make their analysis and secure necessary adjustments in the process. It is always important to check if the schedule is doable and achievable. If it works out well, you can improve it sooner or later.

FAQs

What are the types of maintenance?

There are four types of maintenance: preventive, namely corrective, condition-based, and risk-based.

What are some examples of preventive maintenance?

There are various examples of materials or equipment that undergo regular preventive maintenance. It includes oil changes, lubrication, adjustments, repairs, and replacements.

What are the typical advantages of preventive maintenance?

Among the advantages of preventive maintenance, the most common are efficiency and avoiding delays. These two secures that equipment will work finely and error-free.

Indeed, you need essential equipment for your business to run productively and smoothly. But because these are also materials that are commonly used regularly, you can expect damages. Therefore, you need to schedule preventive maintenance to avoid harmful situations. Follow the steps above and prepare your document for better equipment performance in the workplace.