What is a pulley?

A wheel used to measure time

A device that changes the direction of a force

A tool used for cutting

A type of lever

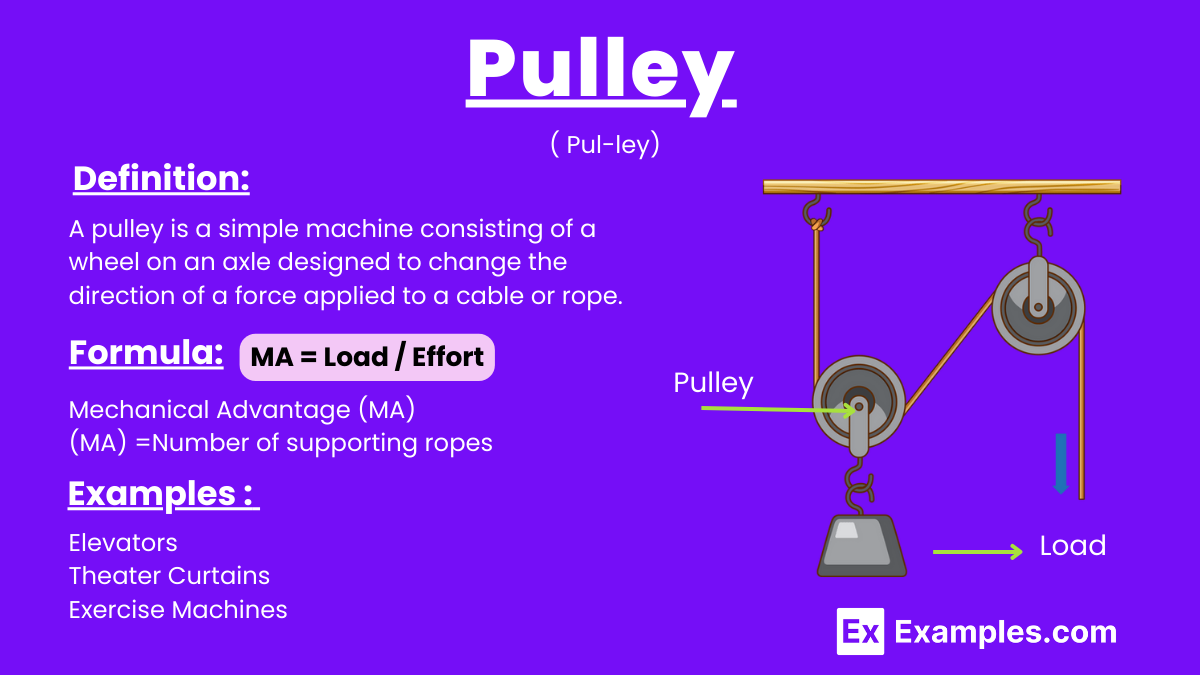

Pulley is a simple machine consisting of a wheel with a grooved rim through which a rope or chain runs. It is used to change the direction of a force, making it easier to lift or move heavy objects. Pulleys can be used singly or in combination to form a pulley system, increasing mechanical advantage and reducing the effort needed to lift a load. Common applications include lifting equipment in construction, raising sails on ships, and various mechanisms in machinery and exercise equipment.

A pulley is a simple machine consisting of a wheel on an axle designed to change the direction of a force applied to a cable or rope. Used in lifting devices like cranes and elevators, pulleys make lifting heavy loads easier by distributing weight over multiple wheels, thus reducing the required input force. Combining multiple pulleys, known as a block and tackle, further increases lifting efficiency.

The pulley formula helps determine the mechanical advantage (MA) of a pulley system, which indicates how much a pulley reduces the effort needed to lift a load. The formula is:

For a system of pulleys, the mechanical advantage can also be calculated by counting the number of supporting ropes (not including the rope attached to the effort force):

Mechanical Advantage (MA)=Number of supporting ropes

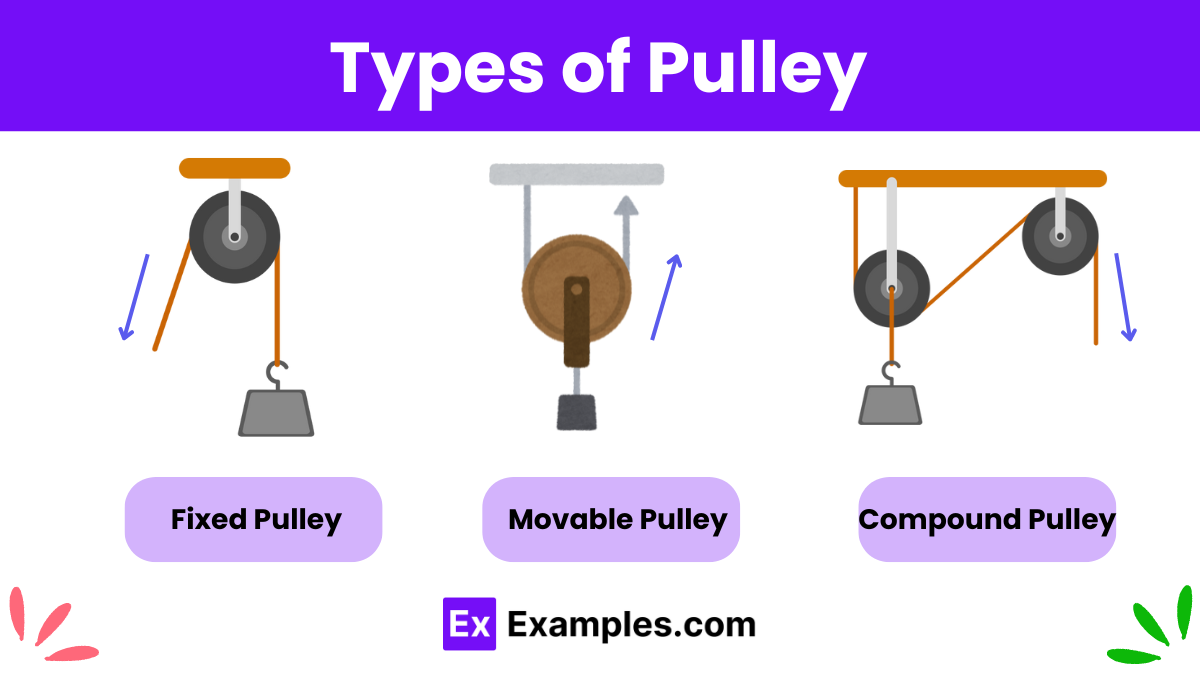

1. Fixed Pulley A fixed pulley has an axle that is anchored in a fixed position. It changes the direction of the force needed to lift a load but does not change the amount of force needed. This type is commonly used in flagpoles and window blinds.

2. Movable Pulley A movable pulley has an axle in a movable block. It reduces the amount of input force required to lift a load. This type is often used in construction cranes and gym equipment.

3. Compound Pulley A compound pulley combines both fixed and movable pulleys. This system, also known as a block and tackle, significantly reduces the input force needed to lift heavy objects. It is widely used in lifting heavy cargo and rescue operations.

4. Block and Tackle A block and tackle system consists of two or more pulleys (fixed and movable) working together to lift heavy loads with minimal effort. This configuration is often used in ship rigging and industrial lifting.

5. Cone Pulley A cone pulley has a conical shape and is used to change the speed or torque in mechanical systems, like in lathe machines and conveyors.

6. Step Pulley A step pulley consists of a series of pulleys of different diameters stacked together, allowing for variable speed control. It is commonly used in machinery like drill presses.

7. V-Groove Pulley A V-groove pulley has a V-shaped groove that grips the belt, providing better traction and reducing slippage. This type is frequently used in automotive engines and industrial machinery.

Pulleys are versatile tools widely used in various applications:

A pulley changes the direction of the force applied, allowing easier lifting of heavy objects by distributing weight over a larger distance.

The mechanical advantage of a pulley system is the ratio of the output force to the input force, making lifting easier.

Divide the load force by the effort force. For multiple pulleys, count the number of supporting ropes.

Pulleys are commonly made from metal, plastic, or wood, depending on their application and load requirements.

Yes, pulleys can reduce the amount of effort needed to lift or move heavy objects by distributing the load.

A belt and pulley system uses a belt looped around pulleys to transfer motion and power between shafts, often used in machinery.

Pulleys assist in various tasks like raising flags, lifting construction materials, and adjusting window blinds, making tasks easier.

A block and tackle system is a combination of pulleys with ropes or cables, designed to provide a significant mechanical advantage.

Friction in pulleys can affect their efficiency by causing resistance, so minimizing friction helps improve performance and ease of use.

Regularly check for wear and tear, lubricate moving parts, ensure ropes or belts are in good condition, and replace damaged components promptly.

Text prompt

Add Tone

10 Examples of Public speaking

20 Examples of Gas lighting

What is a pulley?

A wheel used to measure time

A device that changes the direction of a force

A tool used for cutting

A type of lever

Which type of pulley system provides a mechanical advantage by reducing the amount of force needed to lift an object?

Fixed pulley

Movable pulley

Single pulley

Electrical pulley

How does a fixed pulley work?

It moves with the load

It stays in one place and changes the direction of the force

It provides a mechanical advantage by reducing the load

It increases the speed of the load

Which of the following systems combines both fixed and movable pulleys?

Block and tackle

Single pulley

Double fixed pulley

Electrical winch

What happens to the tension in the rope when using a single movable pulley?

The tension doubles

The tension remains the same

The tension halves

The tension increases tenfold

How does a pulley system affect the amount of work done?

It increases the total work done

It decreases the total work done

It does not change the total work done

It creates work

Which factor determines the mechanical advantage of a pulley system?

The number of pulleys

The length of the rope

The speed of pulling

The weight of the pulley

What is the primary purpose of using a pulley in a flagpole system?

To reduce friction

To change the direction of the force applied

To increase the flag’s weight

To decrease the rope length

What is the mechanical advantage of a pulley system with four supporting ropes?

1

2

4

8

Which type of pulley would be most effective for lifting heavy loads with minimal effort?

Single fixed pulley

Single movable pulley

Combined pulley system

Double fixed pulley

Before you leave, take our quick quiz to enhance your learning!