What is the primary alloying element in stainless steel that gives it its corrosion resistance?

Copper

Chromium

Zinc

Nickel

Stainless steel, a remarkable achievement in the world of chemistry and materials science, stands out as a metallic compound known for its incredible resistance to rust and corrosion. This unique alloy, primarily composed of iron, carbon, and a significant amount of chromium, undergoes a fascinating chemical reaction that creates a thin, protective layer on its surface. This layer is what shields the steel from environmental factors that typically cause metals to deteriorate. Widely celebrated for its durability and strength, stainless steel plays an essential role in various industries, making it a cornerstone material in the creation of everything from kitchen utensils and appliances to medical instruments and construction materials.

This type is the most common. It’s made with a combination of iron, chromium, and nickel, giving it great strength and excellent corrosion resistance. Austenitic stainless steel is popular in kitchenware, plumbing, and architecture for its corrosion resistance and versatility in shaping.

Ferritic stainless steel is similar to austenitic but has more chromium and less nickel. This makes it magnetic and less expensive. It’s strong, resists corrosion well, and is used in appliances like washing machines and industrial equipment. However, it’s a bit less durable than austenitic stainless steel.

Martensitic stainless steel, with less chromium and more carbon, is harder and stronger but not as corrosion-resistant. It’s perfect for sharp, durable items like cutting tools and surgical instruments, thanks to its heat-treatable nature for enhanced strength.

Duplex stainless steel combines the features of austenitic and ferritic stainless steels. It has high levels of chromium and also includes nickel and molybdenum. This mix gives it twice the strength of regular stainless steel and even better resistance to corrosion. It’s used in harsh environments like chemical plants and seawater desalination plants

Stainless steel is a strong and durable metal that’s used in everything from kitchen utensils to building structures. At its core, stainless steel is made up of iron, which is combined with a small amount of chromium. This mix is what gives stainless steel its unique properties. The addition of chromium to iron forms a protective layer on the surface, shielding the metal underneath from rust and corrosion. This is why stainless steel can resist rust so well, making it perfect for many uses.

Depending on what it will be used for, stainless steel might also include other elements like nickel, molybdenum, or nitrogen. These elements can change how the stainless steel behaves, like making it more flexible or even more resistant to corrosion. The exact combination of these elements affects the stainless steel’s structure and properties, allowing it to be customized for different uses. This flexibility and durability make stainless steel an essential material in many industries.

The creation of stainless steel begins with mixing iron ore, chromium, and sometimes nickel and other metals, in a large furnace. This mixture is heated at extremely high temperatures until it melts together. The basic chemical reaction for making stainless steel involves combining iron (Fe) with chromium (Cr), and often nickel (Ni), to create a base alloy.

This is a simplified view, as the actual process involves precise measurements and conditions to achieve the desired properties.

Once the metals are fully melted and mixed, the liquid steel is cast into molds to solidify. After solidification, it undergoes various processes like hot rolling, which shapes the steel into sheets, bars, or other forms. Finally, it’s treated with heat and sometimes cold to strengthen it and adjust its structure for use in everything from kitchenware to buildings. The addition of chromium is crucial as it forms a thin protective layer of chromium oxide on the steel’s surface, preventing rust and making the steel “stainless.”

| Property | Description |

|---|---|

| Strength | Stainless steel is very strong, capable of withstanding high forces without bending or breaking. |

| Corrosion Resistance | It resists corrosion and rusting very well, thanks to the chromium content that forms a protective layer on its surface. |

| Heat Resistance | Stainless steel can withstand high temperatures, making it ideal for use in environments exposed to intense heat. |

| Magnetic Properties | Some types are magnetic (like ferritic and martensitic), while others (like austenitic) are not. |

| Flexibility | Despite its strength, stainless steel can be formed into a variety of shapes and sizes, offering great flexibility in its use. |

| Durability | It is highly durable and maintains its appearance and properties over a long time, even in harsh conditions. |

| Conductivity | Stainless steel is not a great conductor of electricity or heat compared to metals like copper, but it’s sufficient for many applications. |

| Density | It has a relatively high density, making it heavier than some other materials, which contributes to its strength and durability. |

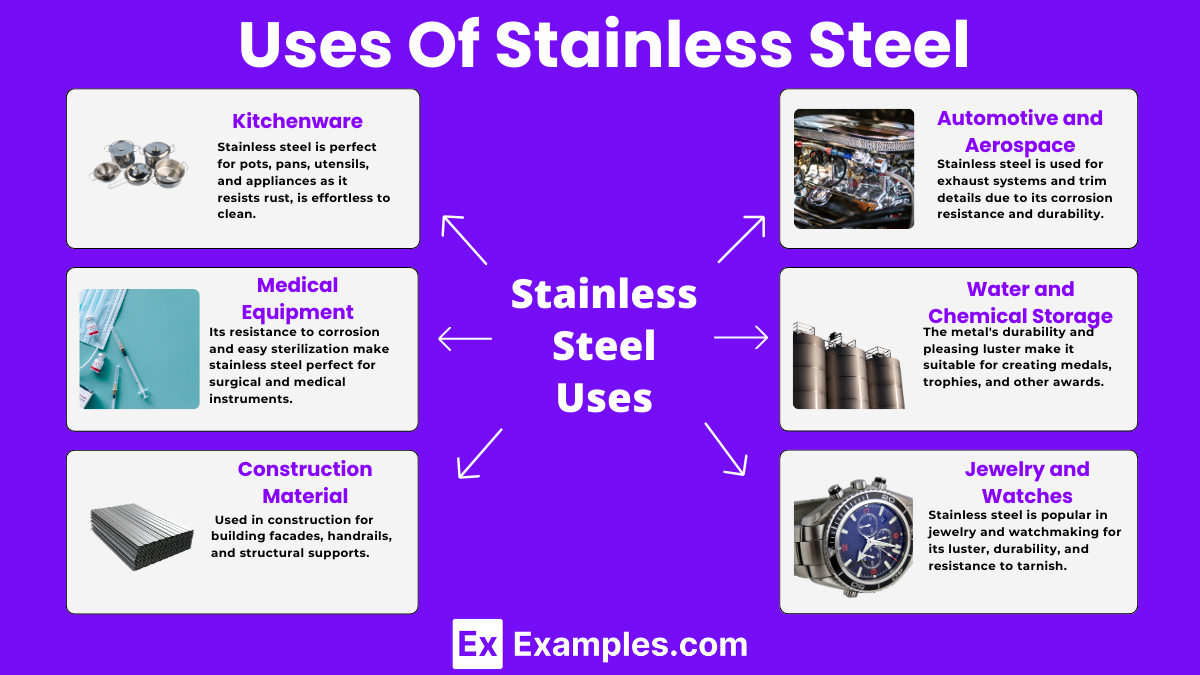

Stainless steel is perfect for pots, pans, utensils, and appliances as it resists rust, is effortless to clean, and doesn’t interact with acidic foods, ensuring they remain safe and devoid of metallic flavors.

Its resistance to corrosion and easy sterilization make stainless steel perfect for surgical and medical instruments, implants, and hospital equipment, ensuring they remain safe for patient use.

Stainless steel is used in construction for building facades, handrails, and structural supports because of its strength, durability, and resistance to weathering, maintaining its appearance over time.

Stainless steel is used for exhaust systems and trim details due to its corrosion resistance and durability. Aerospace applications include parts for aircraft and spacecraft that require materials to withstand extreme conditions.

Tanks and pipes for storing and transporting water, chemicals, and gases often use stainless steel because it doesn’t corrode easily, ensuring the safety and purity of the contents.

Stainless steel is popular in jewelry and watchmaking for its luster, durability, and resistance to tarnish, making it an attractive and practical choice for everyday wear.

Stainless steel, renowned for durability and rust resistance, is widely used for knives, forks, and spoons. It stays shiny and sharp even with frequent use.

Stainless steel is known for its exceptional durability. It resists corrosion, rust, water stains, and impact, ensuring that products made from it have a long life span.

Stainless steel’s smooth surface simplifies cleaning, making it ideal for hygiene-sensitive industries like food processing and healthcare.

Stainless steel is 100% recyclable, reducing the environmental impact. Its longevity also means less need for replacement, leading to reduced waste.

Despite its lightweight, stainless steel provides high strength, particularly in alloys, enabling thinner materials to uphold structural integrity.

Stainless steel’s durability and corrosion resistance result in less maintenance, saving time and money over its lifespan.

Good quality stainless steel contains high chromium and nickel content, enhancing corrosion resistance and strength. Grades 304 and 316 are prime examples of high-quality stainless steel.

No, stainless steel is not 100% stain-proof. While highly resistant to rust and corrosion, stainless steel can still stain or corrode under extreme conditions or if not properly cared for.

316 stainless steel surpasses 304 in salty or chlorinated environments because of its higher molybdenum content. This leads to superior corrosion resistance.

Normally, 304 stainless steel is cheaper than 316 due to its lower molybdenum content. This makes it cost-effective for many applications while still offering corrosion resistance.

Text prompt

Add Tone

10 Examples of Public speaking

20 Examples of Gas lighting

What is the primary alloying element in stainless steel that gives it its corrosion resistance?

Copper

Chromium

Zinc

Nickel

Which type of stainless steel is known for its high corrosion resistance and is commonly used in medical instruments?

Austenitic

Ferritic

Martensitic

Duplex

What property of stainless steel makes it particularly suitable for use in marine environments?

Hardness

Electrical conductivity

Corrosion resistance

Density

Which stainless steel grade is commonly used for kitchen utensils due to its balance of strength and resistance to rust?

304

316

430

201

What characteristic of stainless steel is enhanced by adding nickel to the alloy?

Magnetism

Thermal conductivity

Corrosion resistance

Color

Which type of stainless steel is known for its high tensile strength and is often used in applications requiring hardness and wear resistance?

Austenitic

Ferritic

Martensitic

Duplex

What feature distinguishes ferritic stainless steel from other types?

High carbon content

High chromium content

High nickel content

High ductility

What is the main difference between duplex stainless steel and other types of stainless steel?

It contains no chromium

It has a dual-phase microstructure

It is not magnetic

It is used only in aerospace applications

Which element is added to stainless steel to improve its formability and toughness?

Carbon

Molybdenum

Manganese

Titanium

How does the addition of molybdenum affect stainless steel?

It improves corrosion resistance in acidic environments

It reduces ductility

It increases magnetic properties

It enhances weldability

Before you leave, take our quick quiz to enhance your learning!